The activated sludge process developed in The activated sludge process developed in 1914 in England is definitely the old timer of this group. This combination system saw its first.

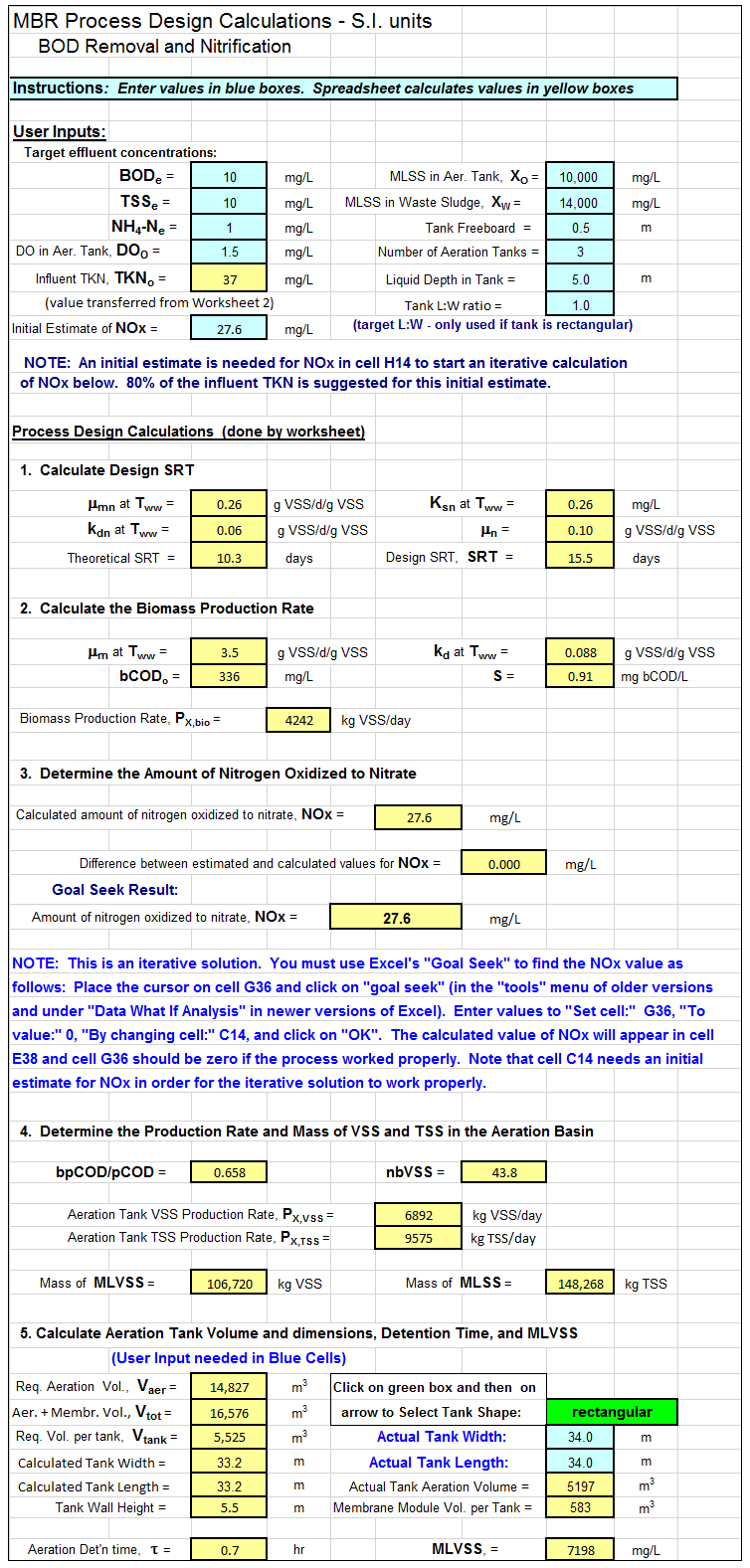

Input Screen For Mbr Module Part 1 Figure 7 Input Screen For Mbr Download Scientific Diagram

You will learn how to optimize processes and monitor critical parameters for scale-up.

. Real-time gas analysis enhances efficiency safety throughput product quality and ensures environmental compliance. Typically the membrane is either low-pressure microfiltration or ultrafiltration and the suspended growth step is an activated sludge process. Practical sessions include bioreactor inoculation and.

This process is widely used for industrial and municipal wastewater treatment process. Case Study of Tikrit WWTP. We also discuss validation and process design considerations for good manufacturing practice GMP.

A significant difference in the volume of secondary treatment was obtained from design calculations where the CAS without d e-nitrification system was 9244 m3 aerobic and. So how does the MBR Membrane Bioreactor work. Membrane Bioreactor Using GPS-X Simulation Program.

Obtained results from both hand calculations and the results of the program showed a good agreement. This module is part of the Advanced Diploma in Chemical Engineering. Unlike the polishing process the MBR is used as a tertiary water treatment step that has no return of active biomass to the.

Gas analysis can utilize various technologies such as tunable diode laser spectroscopy zirconia oxygen analysis infrared gas analysis stack gas analysis dust monitoring process gas chromatography continuous emissions monitoring systems CEMS. The basic design principles and optimal process stages for multiple stage evaporation and crystallization processes will be considered. The knowledge obtained in this course will assist students with troubleshooting optimisation and designing of a complex separation systems in a chemical.

MOLES AND MOLAR FLOW RATES 207 61 The Molar Flow Rate Balance Algorithm 208 62 Mole Balances on CSTRs PFRs PBRs and Batch Reactors 208 621 Liquid Phase 208 622 Gas Phase 210 63 Application of the PFR Molar Flow Rate Algorithm to a Microreactor 212 64 Membrane Reactors 217. CHAPTER 6 ISOTHERMAL REACTOR DESIGN. Membrane bioreactor MBR is a wastewater treatment system that combines a membrane process with a suspended growth biological treatment method.

2 the FA and FNA concentrations of the bioreactor is presentedRelative to ammonium N H 4 easier diffusion of FA across the anammox cell membrane has led to numerous researchers considering it as the main reason to a possible performance degradation rather than the high influent N H 4 concentration Talan et al 2021The comprehensive study by Zhou. This course covers bioreactor cultivation and upstream process development strategy using single-use equipment. The MBBR process is also made more perfect by the use of MBR Membrane Bioreactor.

Amazon Com Spreadsheets For Mbr Wastewater Treatment Process Design Calculations Ebook Bengtson Harlan Books

Amazon Com Spreadsheets For Mbr Wastewater Treatment Process Design Calculations Ebook Bengtson Harlan Books

Plutocalc Designer Handbook Mbr For Bod And Nh4 Removal

Standard Membrane Bioreactor Computations Mcgraw Hill Education Access Engineering

Membrane Bioreactor Wastewater Treatment Calculations Spreadsheet Low Cost Easy To Use Spreadsheets For Engineering Calculations Available At Engineering Excel Spreadsheetslow Cost Easy To Use Spreadsheets For Engineering Calculations Available At

Membrane Bioreactor Wastewater Treatment Calculations Spreadsheet Low Cost Easy To Use Spreadsheets For Engineering Calculations Available At Engineering Excel Spreadsheetslow Cost Easy To Use Spreadsheets For Engineering Calculations Available At

0 comments

Post a Comment